Manufacturing Execution Systems

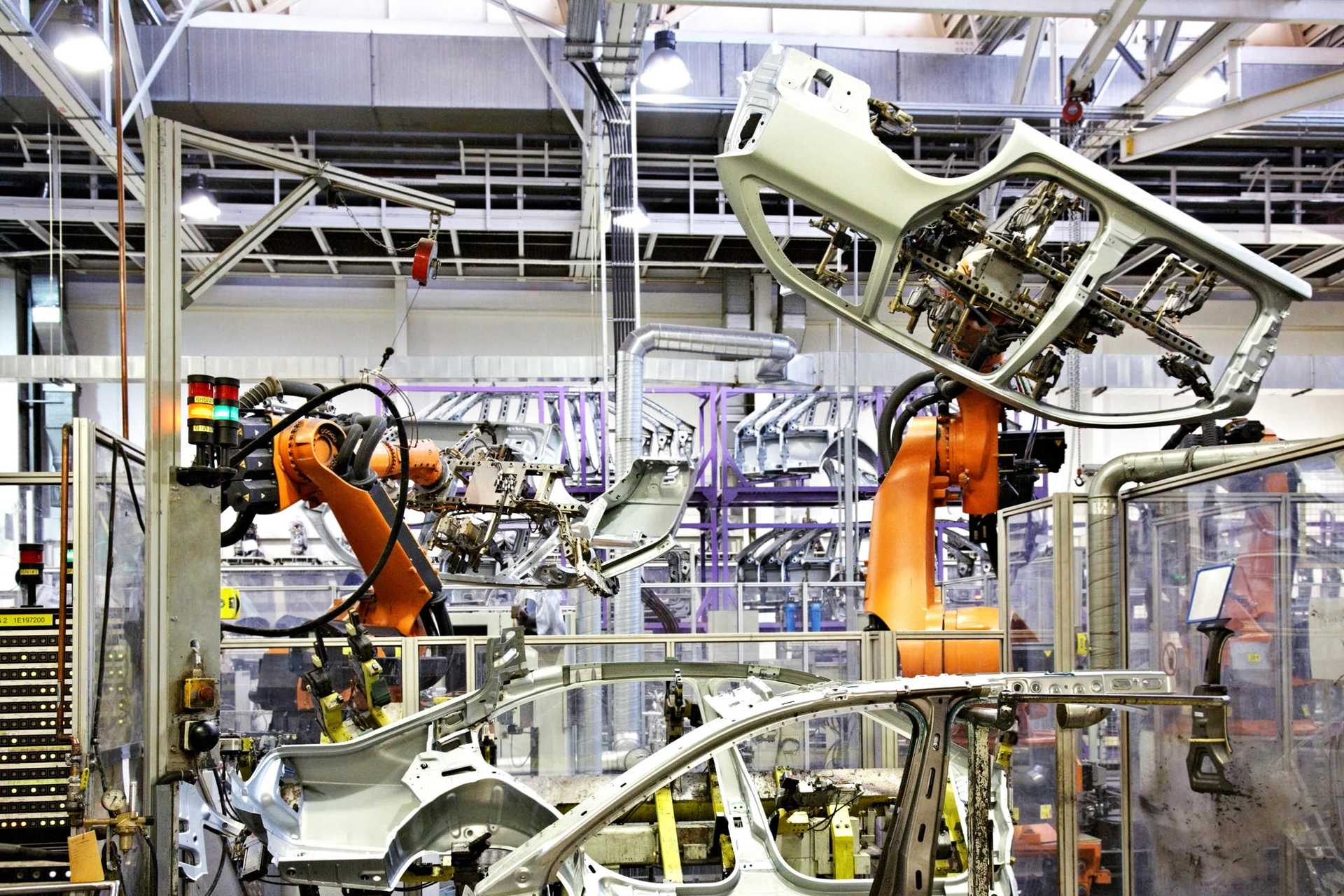

Transform Your Shop Floor with MES Software

Transform Your Shop Floor with MES Software

A Manufacturing Execution System (MES) is the backbone of modern smart manufacturing. Our MES software connects your enterprise resource planning (ERP) systems with the shop floor, providing real-time visibility, control, and optimization of every production process.

With MES, you can monitor every step of production, enforce best practices, and make smarter decisions that drive efficiency, compliance, and profitability

Over several years QIC has carefully vetted multiple MES software providers. We’ve partnered with a select few to invest our time and energy to develop deep technical skills in order to help our clients to plan, deploy, and support their MES projects.

Why implement MES?

MES delivers measurable results across the entire manufacturing process.

Increase productivity and maximize equipment utilization.

Ensure consistent, high-quality output across every production run.

Reduce waste, scrap, and downtime through smarter process control.

Enable end-to-end visibility, traceability, and compliance.

What Our MES Delivers for Manufacturers

Optimize job sequencing, reduce bottlenecks, and boost throughput.

Real-time progress tracking ensures orders are delivered on time.

Enforce in-process inspections, minimize rework, and comply with industry standards.

Achieve full product history tracking for audits, recalls, and customer trust.

Reduce stockouts, eliminate excess inventory, and improve forecasting.

Track Overall Equipment Effectiveness to identify losses and improve efficiency.

Reduce unplanned downtime and integrate predictive maintenance strategies.

Standardize work instructions, reduce variability, and ensure compliance.

Stay audit-ready with electronic records that meet FDA, GMP, and ISO standards.

Leverage real-time dashboards and KPIs for better decisions and continuous improvement.

Business Benefits of MES Software

Faster time-to-market with smarter, more flexible processes

Lower production costs and higher margins through efficiency gains

Consistent, high-quality products that strengthen customer satisfaction

Better ROI with optimized use of equipment and labour

Stronger compliance posture and reduced regulatory risk

Why Choose QIC as your MES Solution Partner?

Our MES partners design solutions built for Industry 4.0 — combining real-time data, automation, and process intelligence so manufacturers can thrive in competitive markets.

Ready to Optimize Your Shop Floor?

Connect your ERP to the factory floor and gain real-time control. Contact QIC to find the right MES partner for your unique production needs.